Other Articles

- Mestex Covid-19 Notice

- Mestex Covid-19 Update

- Video Introduction of the New Aztec AMC Evaporative Cooling Air Turnover System

- Designing Data Centers as Thermos Bottles

- A New Video on YouTube Describing How the Aztec Evap System Works

- SHOWTIME!!!

- Aztec To Be In Capacity North America Exhibit Hall

- Virtual Reality

- A Simple Concept That Saves Big Dollars

- Indirect Evaporative Cooling Research Project Launched

- Canadian Patent Granted for Mestex Digital High Turndown Burner

- Aztec Provides Fresh Air Intake Penthouses for Data Centers in Northwestern US

- Shading and Make-Up for Building Designers

- Credibility and Trust

- How I Spent My Summer Vacation

- Too Hot to Handle? A Simple Reminder.

- Preaching to the Choir

- Evaporative Cooling Anaysis for Data Modules in Two Diverse Climates

- Aztec Indirect Evaporative Cooling System on Display at DFW ASHRAE Golf Outing

- How We Used To Do It

- Air Pollution and HVAC

- Aztec Evaporative Cooling for Data Centers at Data Center World

- Mestex, Division of Mestek YouTube Channel

- GreenBuild Toronto

- Trane Division of Ingersoll-Rand in Lawsuit Over Wireless Technologies

- New BIM Objects From The Aztec Brand

- DOE Proposes Building Rating System

- The Importance of Correct Static Pressure for Direct Fired Make-Up Air Equipment

- Instant Online Document Lookup Using Microsoft Tags

- Do Evaporative Cooling Systems Use Too Much Water?

- Sustainability at Mestek Dallas

- Facebook Offers Their Outside Air Cooling Solution To All Data Center Owners

- Restaurant Energy Saving Idea That Can Be Used Anywhere

- Planning for Volatility

- Ever Wonder Where the Power Goes in a Data Center?

- ASHRAE TC 9.9 Expands Data Center Temperature Ranges Again

- Green Buildings Get Another Boost

- ASHRAE Show Report

- The Story of SHR or Why My Classroom is Stuffy

- CFD, Air Turnover, and the Pharmaceutical Industry

- It is not sustainable if it is not maintainable... or if it breaks down

- Accounting Rule Change Might Impact HVAC

- Reduce electrical demand load with an Aztec indirect evaporative cooling unit

- Lower Cost of Ownership with the Applied Air FAP

- Everything You Want to Know in a Flash

- Data Centers and Evaporative Cooling Webinar August 23

- New "Green" Product Announcement

- DDC Application Case Studies

- PowerPoint showing the importance of gas pressure, static pressure, and voltage

- Webinar: 'The Importance of Correct Gas Pressure, E.S.P. and Voltage'

- An Old Solution to a New Problem

So You Think Your Critical HVAC System Is Reliable?

I just read an article in Engineered Systems magazine that reminded me of one of my own blog postings from a few months ago. The difference is that the author in the ES magazine article went all mathematical on us and showed the formulas for calculating HVAC system reliability given the reliability of the individual components in the system. Although it was a long time ago I remember going through the mathematical exercise in one of my engineering courses back at the University of Texas...so we have all known about this procedure for a very long time.

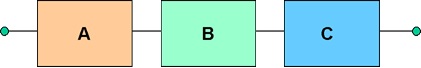

During this same week I have been asked to do a competitive analysis on a "new" system concept compared to one of our systems. While I could name names that is not necessarily the important point of this posting. What struck me about the competitor's "new" system concept was just how many parts were required to accomplish the task of providing "free cooling". Many of those component parts had dependencies that meant that the proper reliability analysis was the "series" analysis. You can refer to the latest issue of Engineered Systems if you don't remember what that means but in keeping with my simple approach to my postings the bottom line is that the reliability of a "series" of components is the compounded product of each item's reliability multiplied together. In other words if the "new" system concept required 4 compressors that are staged in series, a direct drive exhaust fan array, a direct drive supply fan array, a sensible heat wheel motor, sensible heat wheel belt, sensible heat wheel bearings, digital control module, etc...and we gave each of those items a reliability of 98% (which sounds pretty good and is generous for some of the items in the chain)...then the "system" reliability would be:

.98 x .98 x .98 x .98 (compressor section) x .98 (exhaust fan) x .98 (supply fan) x .98 (sensible heat wheel motor) x .98 (sensible heat wheel belt) x .98 (sensible heat wheel bearings) x .98 (digital control module) = .817

So, the "new" system concept under this scenario would actually have a reliability of only 81.7%...not quite so good I think you would agree.

The information from this example is actually directly from the competitor's product literature...and I left out some components for simplicity sake. The reliability of the components at .98 was an estimate and you can plug in whatever numbers you think are accurate. The important thing is to recognize that the more complex the system is the lower the reliability will be.

In a previous blog posting I quoted Albert Einstein who said ..."make everything as simple as possible, but not simpler.". I still think Albert was a pretty smart guy and when I look at some of the design solutions being proposed today for data centers, pharmaceutical warehouses, or cooling in general I just have to wonder why we sometimes design such complex solutions.

Remember..."it is not sustainable if it is not maintainable"...and, as a corollary to that statement, "it is not maintainable if it is too complex and has too many parts"…