IFJ

IFJ

An Air Turnover Product for Smaller Spaces

Any small business building a new structure will encounter certain unavoidable problems during the course of design. Until now, one area of difficulty was always the design of a heating and cooling system that could save on energy costs and maintain a comfortable working environment for employees.

'Air Turnover Systems' is a designation describing a unique class of commercial and industrial heating or heating and cooling equipment used to condition large spaces. The IFJ is an air turnover system designed for smaller spaces (4,000 to 12,100 CFM) and can also provide cooling via an optional "A"-coil with cooling capacities from a nominal 9.5 to 24 tons.

The Air Turnover principle eliminates air stratification in heated buildings with open spaces. It does this by recirculating hot air which becomes trapped at the ceiling. This is accomplished by removing colder layers which maintain the thermal barrier responsible for the problem. Large volume air movement turns the room air over 1 to 5 times each hour. Continuous air circulation then thoroughly mixes the air to maintain uniform room temperature. This uniform room temperature eliminates the possibility of condensation forming on stored materials because of uneven room temperature. Cold air from open doors in shipping and receiving areas becomes less of a problem with an Air Turnover unit. Termperature recovery is almost instantaneous after doors are closed.

Learn More about Air Turnover Products

Features

Literature

Take a look at our complete Literature Library for even more information

HEATING AND COOLING FOR SMALLER BUILDINGS

Compact Footprint

The Applied Air IFJ is a compact, modular, air turnover unit. The IFJ is also very versatile allowing you to select a unit for heating only or, as in this photo, heating and cooling unit. The modular design allows simple installation. This unit was installed in this 10,000 sq.ft. building by 2 people using a forklift. No ductwork is required with the IFJ. No roof penetrations are required. The unit performs just like any other air turnover unit to provide even temperatures throughout the space.

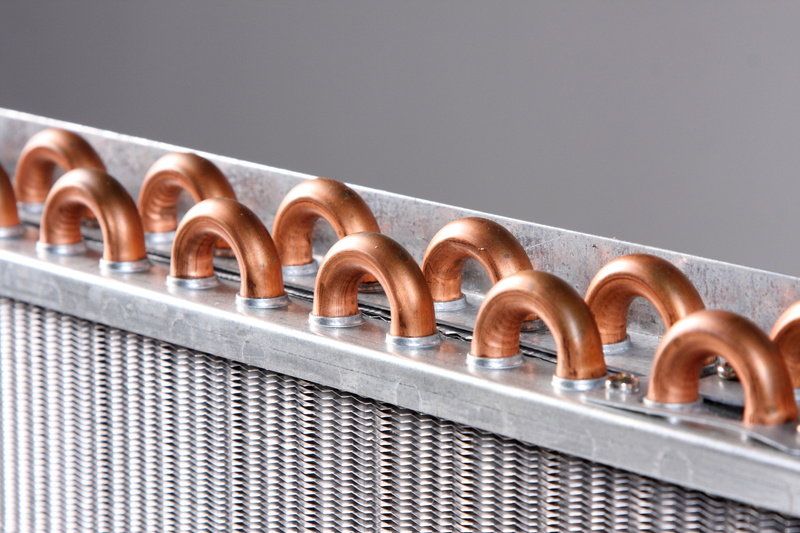

FLEXIBLE COOLING CHOICES TO SUIT YOUR REQUIREMENTS

Industry Standard Coil Designs

The Applied Air IFJ is designed to include two three row (DX) (CW) cooling coils with copper tubes, aluminum fins and galvanized steel casing. The coils are mounted in an “A” coil arrangement with an insulated stainless steel drain pan under each coil. Coil velocities are designed not exceed 550 FPM in order to minimize the risk of moisture carryover.

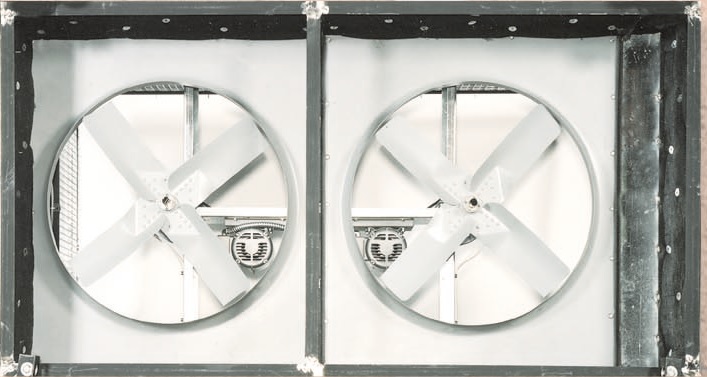

BELT-DRIVEN PROPELLER FANS

Efficient Air Movement

Belt driven turbine four bladed energy efficient propeller fans are driven by single phase or three phase motors mounted on an adjustable base. The propellers are mounted on heavy duty, turned and ground and polished solid steel shafts designed for a maximum operating speed not to exceed 75% of its first critical speed.