IFS

IFS

EMP Series Air Turnover Systems

The IFS (EMP) is a floor mounted unit which utilizes the Air Turnover principle to eliminate air stratification in heated buildings with open spaces. It does this by recirculating hot air which becomes trapped at the ceiling. This is accomplished by removing colder layers which maintain the thermal barrier responsible for the problem.

Large volume air movement is provided by energy efficient propeller fans, which turn the room air over 2.5 to 4 times each hour. Continuous air circulation then thoroughly mixes the air to maintain uniform room temperature.

This uniform room temperature eliminates the possibility of condensation forming on stored materials because of uneven room temperature. Cold air from open doors in shipping and receiving areas becomes less of a problem with an Air Turnover unit. Temperature recovery is almost instantaneous after doors are closed.

The IFS unit is an air moving unit only...it does not contain heating or cooling sections.

The IFS has an air handling range from 9,100 to 150,000 using propellar fans.

Learn More about Air Turnover Products

Features

Literature

Take a look at our complete Literature Library for even more information

DDC CONTROLS ARE OPTIONAL

Patented Precision

The IFS is capable of integrating into a network of air turnover units thanks to the patented Adaptaire DDC control system (Patent #7,059,536). Interfacing with local networks is made easier since the Adaptaire system supports BACnet, LON, N2, and Modbus. IFS units are often used in buildings with very large footprints but relatively small thermal loads. By integrating with other air turnover units the IFS can provide the necessary airflow and help distribute the heated or cooled air efficiently.

LOWER INSTALLATION COSTS

No Ductwork and Stackable Sections

Air is discharged directly at low velocity. No ductwork is required so installed cost is lower. Additionally, the IFS unit is built in modules that are stacked in the field. Each module has lifting lugs and alignment flanges for faster and lower cost installation.

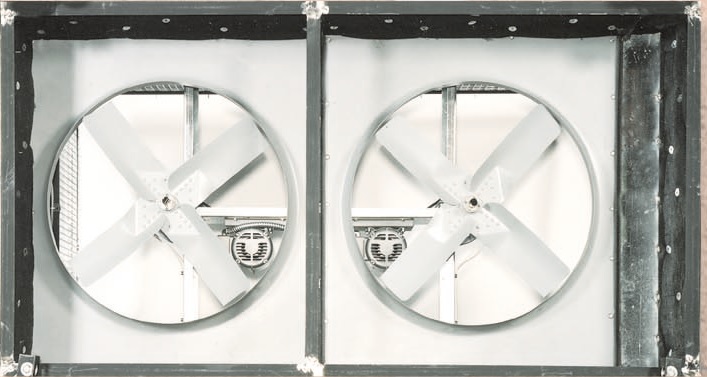

MULTIPLE BELT-DRIVEN PROPELLER FANS

Efficient Air Movement

Multiple belt driven turbine four bladed energy efficient propeller fans are driven by a three phase high efficiency motor mounted on an adjustable base. The propellers are mounted on heavy duty, turned and ground and polished solid steel shafts designed for a maximum operating speed not to exceed 75% of its first critical speed.

FACTORY MOUNTED AND WIRED VFD OPTIONAL

Match Fan Speed to Load

The already lower operating costs of the IFS unit can be further enhanced with the optional VFD for the supply fans. Building thermal loads can vary widely, especially in very large warehouses and factories that might be operating 24/7. Adding the VFD option to the IFS, and integrating it with the Adaptaire DDC system, can result in significant operating cost savings by matching fan speeds to the demands of the building.

DISCHARGE PLENUM

Low Velocity Discharge Air Movement

A low velocity discharge air plenum with screens on three sides is standard on the IFS. Single sided, double sided, and four-sided discharges are optional. In very tall spaces it is also possible to order an extended plenum arrangement in order to position the discharge at the optimal level for the space. Since no ductwork is required installation time and money are saved.