Indirect-Fired Systems

Flexible units for space heating and make-up air applications

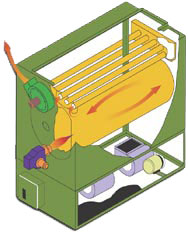

Direct Drive Induced Draft Fan

Efficient, maintenance-free fan and motor assembly add to system gas burning efficiency.

Testing

During construction, Applied Air uses laser technology for bearing alignment. All Applied Air indirect fired units go through a 140 point checklist prior to shipping.

Heat Exchanger

Four pass heat exchanger provides high efficiency, without use of turbulators, and maximum heat exchanger life.

Control Cabinet

Provided with fuses and power transformer for single point electrical connection.

Gas Burner

Power type gas burner for maximum efficiency with optional controls to comply with FM & IRI.

How Indirect Fired Heating Works

Indirect Fired gas heating works by transferring heat from a gas flame to a steel chamber and then to the supply airstream. Each transfer of heat results in a loss of efficiency, and some of the original gas flame heat is lost. The amount of loss can be minimized by:

- Using a powered burner to spread the flame deep down the steel chamber.

- Pulling the flame heated air evenly through all of the steel tubes by using an "induced" draft fan.

- Exposing the supply air to as much tubing as possible by using multiple "passes".

With Indirect Fired gas heating equipment, the burner flame is never introduced into the circulating air stream. All products of combustion are vented outdoors through the exhaust flue. As a result, in Indirect Fired equipment is ideal for:

- Space Heating

- Make-up air for applications where Direct Fired units are not allowed.

- Heating and ventilating applications.

Applied Air manufactures Indirect Fired equipment with heat output from 250,000 BTUH to 6,000,000 BTUH, and air delivery from 3,500 CFM to 94,000 CFM.

Features and Benefits of our Indirect Fired Heating Systems

- The heavy gauge galvanized steel outer panels are designed to eliminate rust for longer life.

- Blowers tested to AMCA standards assure proper airflow for efficient operation.

- The large surface area of the four-pass stainless steel heat exchanger provides high efficiency, without the use of turbolators, and maximum heat exchanger life.

- The 140 point final test procedure for every Applied Air indirect fired unit means fewer start-up problems.

- For maximum flexibility, units can be mounted indoors or outdoors, horizontally or vertically.

- Applied Air Indirect Fired units are 80% efficient and operate above condensing temperature.

- The power venter ensures that all products of combustion are properly vented, even in a negative building.

Our flexible, "modular" IF Indirect Fired heating systems add warm, fresh and clean air to your work environment at the highest practical efficiency of 80%.

Improves Comfort Anywhere

IF units are available for indoors (IF), outdoors (IFW), or roof curb mounting (IFR). You can even add DX or chilled water cooling coils for a total comfort solution.

Replaces Indoor Air

The IF line replaces indoor air that can become chemical laden in a painting or processing operations, but without adding dust.

Replaces Lost Heat

Large volumes of exhaust air from kitchen hoods or industrial processes take away lots of heat from the space. IF uits replace the heat efficiently.

Heats Small or Large Buildings

With airflows from 2,500 to 94,000 CFM and heat outputs from 350,000 to 6,000,000 BTUH, you can heat any size building.

Heats Without Condensation

The IF product line operates at efficiencies of 80% in order to avoid the highly corrosive effects of condensation inside the heat exchanger tubes. Efficiencies over 80% can cause serious problems for normal heat exchanger materials.